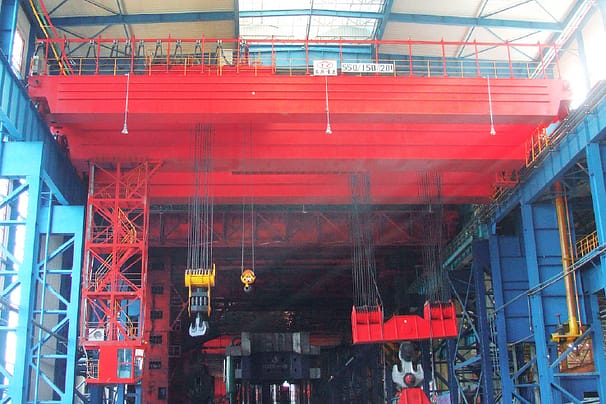

The World's First Largest Hydropower Bridge Crane (1,300T)

-

1300T

Lifting Capacity -

Hydropower Plants

Application Sectors -

Overhead Cranes

TZCO Equipment -

Yunnan, China

Country

Korea's largest steel manufacturer: TZCO six 480t casting crane

-

480/100T

Lifting Capacity -

Steel Industry

Application Sectors -

Casting Cranes

TZCO Equipment -

POSCO, Korea

Country

Subscribe To TZCO

Get All The Latest Offers And Products Price Straight To Your Mailbox Every Month.

Metallurgical Specialized Cranes Equipment

TZCO CRANES offering encompasses the entire steel production processFrom mining to final storage, including key stages such as wharf operations, coking, sintering, ironmaking, steelmaking, and rolling.

Selecting the Perfect Overhead Cranes for Metallurgical Applications

Handling & Loading

Refining Area

Area

Raw Material Handling & Loading

Flexible handling of rolled material with high maneuverability and durability. Durable and easy to maintain, it reduces downtime and maintenance costs.

- High Temperature Resistance

- Corrosion And Wear Resistance

- Explosion-proof Design

- Powerful Load Capacity

- Stable Structural Design

Blast Furnace Area

Foundry Crane - Ladle Lifting: For the transportation of molten iron tanks from the blast furnace outlet with high load capacity.

- With heat-resistant materials and cooling systems to protect electrical components and mechanical structures from high temperatures.

- Safety protection devices and emergency stop system to ensure the safety of personnel and equipment.

- Dust and corrosion prevention: with good corrosion resistance, prolonging its service life.

Liquid steel transfer and refining area

Metallurgical casting cranes: For transferring liquid steel and operating refining furnaces with good resistance to high temperatures and advanced control systems and positioning technology.

- Double and quadruple girder casting cranes with high load carrying capacity up to 520t.

- Good corrosion and abrasion resistance and high-precision positioning control system.

- High-temperature resistant design: driver's room and electrical room are fully insulated on all sides.

Steel Rolling Shop

Clamping Cranes: Fast, precise clamping and movement of slabs improves material handling efficiency.

- Flexible handling of rolled material, high mobility and durability.

- The high precision control system and positioning technology allows for accurate placement of slabs in the designated location.

- The machine is durable and easy to maintain, reducing downtime and maintenance costs.

Finished product area

Electromagnetic hanging girder cranes: Used for handling and stacking finished steel products, typically with large span and capacity, equipped with automated control system.

Safety protection: Includes limit switch, overload protection, power failure protection, etc., ensuring operational safety.

Wide range: Suitable for diverse settings and industries like factories, warehouses, wharves, logistics centers, etc., capable of moving metal materials, steel plates, steel pipes, etc.

Electromagnetic Beam Overhead CranesCrane Intelligence: TZCO's Complete Solution

TZCO Cranes according to different scenarios of crane intelligent transformation and digitalization, intelligent empowerment needs, to provide users with a full range of cranes of the whole intelligent solution.Crane

Intelligent

Automatic Crane Operation System

- Multi-Remote Operation

- 3D Positioning & Auto Operation

- Auto Path Planning & Obstacle Avoidance

- Auto Decoupling

- Laser Scanning & Material ID

Multiple Remote Operation

- Multi-operator console for scheduling and operating multiple cranes.

- Switch between remote operation, remote control operation, and driver's room operation with a single key.

- Centralized control of multiple cranes via the crane management system.

Positioning & Automatic Operation

- Utilizes Gray bus, laser range finders, and sensors to receive position commands from production scheduling.

- Automatically moves to specified positions along safe paths.

- Significantly boosts efficiency, minimizes errors

Automatic Dehooking

- Recognizes object shape and coordinates using a laser images scanner.

- Assists the crane's main system in making judgments to ensure safe crane operation.

- Automating unhooking reduces manual work, saving time and labor costs.

TZCO Cranes: Global Hub for Large & Specialized Cranes!

1950

Incorporation500+

First in China & World40000+

Product & Equipment4930000

Land Area70+ Years Crane Experience

70 Years In The Crane Industry, Our Factory Embodies A Blend Of Tradition, Expertise, And Innovation,4000+ Innovation Honors

Awards Span A Wide, Commitment To Quality And Innovation.

500+ No. 1 Rankings in China and the World

500+ In Breakthrough Technologies And Advanced Crane Design.

260+ Projects & Presence in 60+ Countries

Adapting To Diverse Market Needs And Cultural Nuances.

10 Service Stations & 5 Research Base

Experience Our World-class Service, No Matter Where You Are Located.

TZCO Cranes — Multiple park layouts

Multiple campus layouts can help enhance a crane manufacturer's production, R&D and marketing capabilities. It can help increase flexibility, reduce costs and better meet the needs of the global market.TZCO Cranes Blogs

14 days to complete the construction of the crane components

Received customer requirements, the project metallurgical crane needs to complete the bridge structure as soon as possible, in mid-month before the installation, electrical installation, and other follow-up production. In less than half a month, the manufacture of the structural parts of the metallurgical crane of this project was completed the inspection was completed, and the […]

READ MORE

From the “iron frame” to the electrical workshop officially put into production

At the beginning of the establishment of the electrical workshop, the company was still in the budding stage, the electrical assembly manpower was insufficient, the technical level of the staff was also uneven, and can be independently completed only the distribution cabinets, power supply junction boxes, GGD cabinets, and other limited types of parts of […]

READ MORE

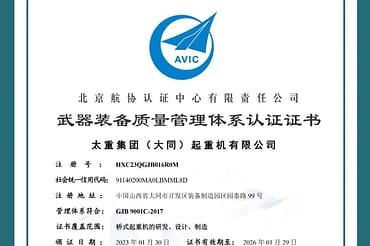

TZCO cranes passed the “national military standard” certification

As we all know, the quality management system of weapons and equipment (hereinafter referred to as the national military standard) certification conditions are very strict. Obtaining the “national military standard” certification indicates that the enterprise has reached a high standard of requirements, and the quality of its military products has been greatly guaranteed. After 11 […]