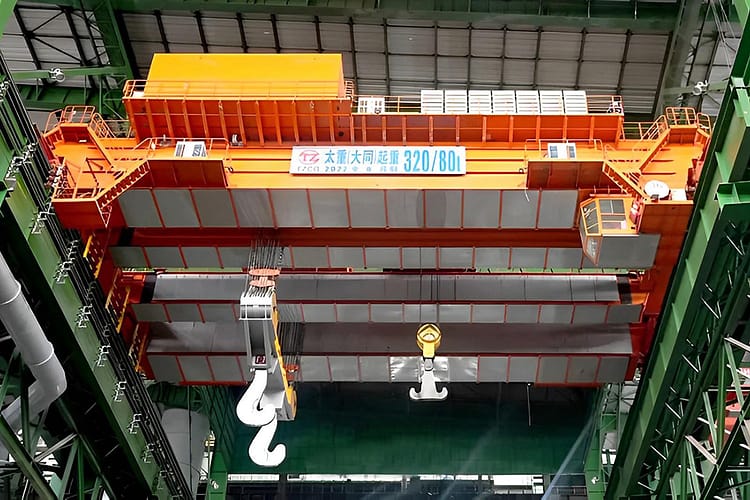

Foundry Overhead Cranes

Foundry Overhead Cranes mainly used for converter charging span to blend iron to converter, refining span to lift steel to refining furnace or steel receiving span to lift steel to continuous casting ladle rotary table.

- Lifting Weight: 50t~520t

- Span: 18m~36m

- Lifting Height: 10m~36m

- Lifting Speed: 3m/min~12m/min

- High Load Capacity

- Reliable and Stable Structure

- High Safety Standards

- Low Maintenance Costs

Product Introduction

Large foundry overhead cranes (over 300 tons) use an integral large reducer model, improving the force condition of the main trolley, avoiding the disadvantage of excessive wheel pressure on the main trolley, and achieving smaller limits for the trolley's left and right movement. This enhances the lifting mechanism's safety and reliability, reduces the number of transmission links, and simplifies maintenance.

For medium and small-sized foundry cranes, models such as double-beam double-track single trolley, double trolley, and trolley with auxiliary trolley can be used. These cranes are characterized by their light weight, small dimensions, and larger single-side limit dimensions, all capable of performing the action of tipping tanks.

Product Features

The main structural forms of casting cranes include: four-beam four-track double trolley, four-beam six-track double trolley, double beam single trolley, and double beam with auxiliary trolley. The structural forms of the main lifting mechanism of large casting cranes include: integral large reducer model, three-reducer model, and double-reducer model.

Key Advantages of Foundry Overhead Cranes

- Enhanced Efficiency: The crane's high load capacity and precision control system contribute to streamlined processes, leading to increased overall efficiency in metallurgical foundry operations.

- Adaptability to Harsh Conditions: Specially designed for the rigors of metallurgical foundry environments, the crane demonstrates resilience in high-temperature conditions, ensuring reliable performance.

- Durability and Reliability: The robust and stable structural design, coupled with low maintenance costs, ensures the crane's longevity and reliability, reducing downtime and maintenance expenses.

- Precise Material Handling: The precision control system enables accurate material handling, contributing to the precise execution of metallurgical processes and minimizing material wastage.

Key Applications Scenarios

TZCO cranes excel in efficiency, adaptability, safety, versatility, durability and precise material handling, making them important lifting equipment for metallurgical casting operations.

Foundry Workshop Transport

Metallurgical Furnace Operations

Process Material Handling

Related Cases

Explore our case studies to discover how our innovative solutions have propelled our clients towards achieving their objectives.Get Started Now!

We Guarantee A Rapid Response To All Your Questions And Inquiries, Ensuring You'll Hear Back From Us Within 24 Hours.

- Email: tzcranes@gmail.com

- Address: No. 99, Yuantai Road, Equipment Manufacturing Park, Economic and Technological Development Zone, Datong City, Shanxi Province, China.